French version

Lors d’une mission post sismique en urgence avec la Croix Rouge Française, au Pakistan en octobre 2005, Guy BESACIER avait proposé de reconstruire les maisons traditionnelles rurales effondrées à cause de leurs murs fragiles en pierres sèches par des maisons en murs de MICROGABION. Il avait remarqué que les protections en GABION des voies sur berges d’une rivière au droit d’une faille étaient encore opérationnelles grâce à son comportement ductile. Il a alors fait le premier croquis d’une maison de 35 m² en MICROGABION avec des paniers classiques mais il a fallu attendre 2009 pour faire évoluer le concept, réaliser deux prototypes au Maroc avec l’association A&D (Architecture & Développement) et pour se rendre compte du potentiel en comprenant le niveau de mise en œuvre requis. Ces deux bâtiments ont été mis en service en 2012 et ont permis de démontrer par l’usage, la pertinence du concept. Puis un programme A&D de reconstruction a été lancé en collaboration avec CRATERRE en Haïti où 50 maisons ont été construites près de Jacmel en 2015.

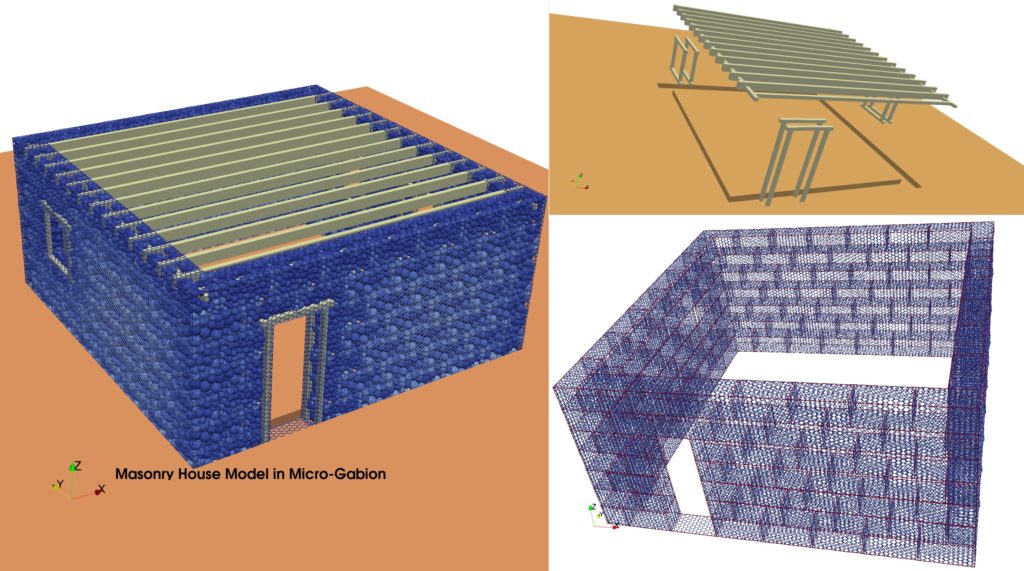

Ce n’est qu’en mars 2020 que la démonstration de la tenue sous charges sismiques a été faite par un calcul aux éléments discrets adapté aux éléments granulaires confinés par le grillage métallique.

English version

During an emergency post-seismic mission with the French Red Cross, in Pakistan in October 2005, Guy BESACIER had proposed to rebuild the traditional rural houses that had collapsed because of their fragile dry stone walls with houses made of MICROGABION walls. He had noticed that the GABION protections of the tracks on the banks of a river near a fault were still operational thanks to its ductile behavior. He then made the first sketch of a 35 m² house in MICROGABION with classic baskets, but it took until 2009 to improve the concept and produce two prototypes in Morocco with Architecture & Development association to realize the potential and understand the level of implementation required. These two buildings were commissioned in 2012 and demonstrated the relevance of the concept through use.

MICROGABION company was created in january 2013 by Guy Besacier

This design office aims to design earthquake and tornado resistant building and to promote MICROGABION technology for this purpose.

Historical

The gabion technology has its origins in antiquity, the earliest known example being the use of systems consisting of woven reed baskets filled with stones for the protection of riverbanks along the Nile, seven thousand years ago. . From such a primitive state characterized by the use of natural materials and empirical knowledge, the idea evolved into a more sophisticated technology involving modern materials and a scientific approach to design and construction in civil engineering but never in building.

The paradox being that it is a simple material to manufacture and cheap but very complex to calculate because it is composed of dry aggregates confined in a steel wire mesh having an anisotropic behavior.

The current technique is based on cages having a rectangular parallelepiped shape, in galvanized mesh filled with pebbles.

The technology we use is a little different: the 6-sided cages no longer exist, they have been replaced by rows formed by an upper bed, a lower bed and vertical U-shaped walls side by side. The connection between vertical mesh and horizontal mesh is made using a simple tool allowing the horizontal edge to be rolled up with the vertical edge. This ensures a continuous bond instead of common one-offs with staples.

The implementation method has been studied in order to create vertical and horizontal walls even on a slope.

We can build seismic and paracyclonic houses with this technology.

We have already built house en Marocco, Haïti and Nepal

It takes only few weeks to complete a single storey house for one family of five persons

The thermal and acoustic insulation is very good due to thick walls.

No need skill workers, you can do it yourself thanks to the guideline to ask at guy.besacier@club-internet.fr